Manipulation, detection and the use of light through excitonic materials can enable a raft of innovative future technologies that stand to benefit all Australians in a multitude of unexpected ways.

Part of the mission for the ARC Centre of Excellence in Exciton Science is to design and create advanced materials with properties specifically defined for target applications that are relevant to Australian industry, such as chemical sensing.

The Centre, through its partnership with the Defence Science and Technology Group (DSTG), is uniquely placed to develop portable and robust chemical sensors with high sensitivity and specificity, to be used, for example, by agricultural workers in detecting pesticide levels.

Of particular interest are fluorescent materials as reporters for sensing events. The capability of the Centre has allowed the investigation of organic/inorganic hybrid materials for this purpose.

Research led by Dr Wenping Yin at Monash University aims to harness inorganic perovskite nanocrystal – a highly efficient fluorescent material - as a means of detecting harmful levels of toxic, volatile organic compounds (VOCs), such as methyl iodide (CH3I) and methyl bromide (CH3Br), used in some agricultural pesticides and wood treatments.

“Methyl iodide has drawn serious biotic and climatic concerns as it has been globally applied, especially over the past decade, while lacking effectual on-site monitoring," Wenping said.

Until now, to precisely detect these toxic gases, you could only do so in laboratories containing specialist equipment and complicated pre-treatments.

"It’s not easy to achieve both the desirable selectivity and sensitivity,” Wenping said.

“Let’s say the worker, farmer or anyone involved in the industry, they need a much easier way to know about the concentration of methyl iodide.”

This challenge prompted Wenping and her colleagues to explore the possibility of developing a high-performance portable, onsite monitoring device.

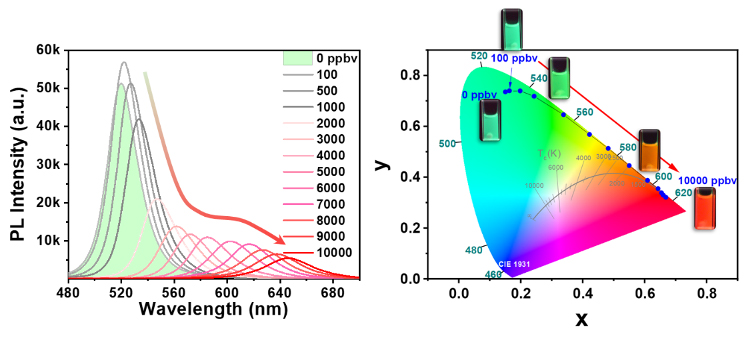

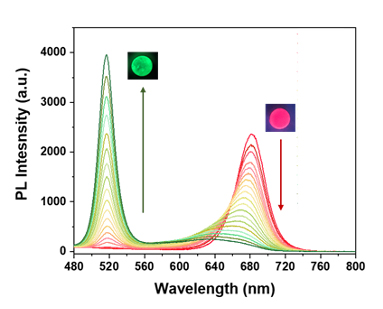

A specialist in time-resolved photoluminescence spectroscopy, Wenping’s work has explored the use of selective reaction perovskites with methyl iodide, and the associated change in emission from green to red, to serve as a sensor indicating the concentration of VOCs levels.

“Although the chemical mechanism sounds very complicated, the outcome is just a visible colourful pattern,” she said.

“We have had something of a breakthrough, because through the results we have filed a patent already. And now we are trying to modify it to achieve a more solid and stable stage. Hopefully we can successfully achieve the creation of a product.”

According to Wenping, discovering the speed at which perovskites react with VOCs represented an important development in progressing the research.

“Perovskite has proven to be surprisingly efficient,” she said.

Perovskite Composite Sensing Performance in Methyl Iodide Liquid Detection.

Colour Coordinate Change of a Perovskite Solid Sensor upon Exposure to Methyl Bromide gas.

“The treatment works really well. We knew perovskite has bright emission and good colour purity. We all knew that. And we all knew that phomagens like methyl iodide and methyl bromide can react with perovskite. But we didn’t know how fast.

“I think the real breakthrough for this work, it was when we figured out a way to break the covalent bond between iodide with the other part, releasing the iodide which subsequently react with perovskite.

“Actually, initially, a lot of the time we were trying to figure out what works well. We checked different references and after that we realised we can utilise the chemical reactions between methyl iodide and a treatment solvent without introducing any side effect. By that, the response time of the sensor was much more improved from a few hours to just a few seconds.

The next phase of the research involves experimenting further with nano/microcrystals to achieve solid states and flexibility, as work continues to develop a functioning device.

“Because we are using the sensor as a liquid base, which is not very practical when making a portable product,” Wenping said.

“So, a near-future step will be how to make it into a solid state. And even in the longer term, make it flexible. Another following issue is how to guarantee the stability of the sensor in ambient.

“Currently we are trying to use microcrystals to increase size and retain brightness but at the same time, make things more stabilised. We have tried porous polymers as well, soft substrate already. The question now is how to make it react homogeneously. So, we are facing challenges but we still have some promising directions to go.”

In addition to the development of fluorescent probes described by Wenping, other research within the Centre has begun to examine substrates for gas and aerosol sensing. These projects are just some of the ways Exciton Science is working towards equipping the Australian Government, businesses and consumers with next-generation excitonic technologies that will help meet the agricultural, industrial and defence challenges of the 21st century.

Monash University